Floating gracefully on expansive oceans, ships are majestic marvels of engineering that conquer vast distances with ease. But beneath their glossy exteriors lies a secret world where maintenance battles are fought day in and day out. Ship hulls play a pivotal role in ensuring seaworthiness in the Philippines, yet they endure constant attacks from formidable adversaries like rust, barnacles, and corrosion. In this enlightening article, we expose four well-guarded secrets of ship hull maintenance that every Filipino seafarer must know by heart. Brace yourself for an odyssey into the captivating realm of preserving these mighty vessels against nature’s unrelenting forces.

Click here to view our ship hull maintenance in Tanza, Cavite, Philippines.

Understanding the Basics of Ship Hulls

When it comes to ship hull maintenance in the Philippines, understanding the basics of ship hulls is crucial. The hull is not just a mere external shell; instead, it acts as the backbone that supports the entire vessel. Different types of ships have different hull shapes and designs that optimize their performance based on various factors.

One vital aspect to consider when studying ship hulls is hydrodynamics. Hydrodynamics deals with how water flows around and interacts with the hull. The shape of the hull influences factors such as drag, wave resistance, and stability. By understanding these principles, shipowners can make informed decisions on maintaining or modifying their vessels to improve efficiency.

Another key aspect of ship hulls is material selection. The choice of materials for building a ship’s hull depends on several factors, like cost, strength, durability, and weight considerations. Traditional wood has been replaced by steel in most commercial vessels due to its superior strength and longevity. However, considerations must be made based on maintenance requirements specific to different materials.

Having a comprehensive understanding of ship hulls is crucial for effective maintenance strategies. Understanding hydrodynamics helps enhance vessel performance while adopting suitable materials ensures longevity and durability in harsh marine environments. By being knowledgeable about these fundamental aspects of ship construction, shipowners can make informed decisions regarding maintenance practices that lead to efficient operations and increased profitability in the long run.

Types of Ship Hulls and their Materials in the Philippines

In the Philippines, ships have varying types of hulls, each designed to suit specific purposes and conditions. One common type is the single-hulled design, where the ship has a single shell or skin for buoyancy and protection. This type is less expensive and easier to build than others. However, double-hulled ships are becoming more popular due to stricter regulations for environmental safety. These ships have an additional inner layer that acts as a barrier against oil spills in the event of accidents.

When it comes to materials used for ship hulls in the Philippines, steel remains the most prevalent choice due to its durability and strength. Steel is able to withstand harsh weather conditions, as well as collisions with other objects or vessels. Additionally, steel can be easily modified or repaired without compromising structural integrity. Another material gaining traction is fiberglass-reinforced plastic (FRP), known for its lightweight properties combined with a high strength-to-weight ratio. FRP offers resistance against corrosion from saltwater exposure, making it ideal for maritime applications in tropical regions like the Philippines.

Understanding the different types of ship hulls and their materials is crucial in maintaining a resilient fleet in the Philippines’ maritime industry. Selecting appropriate designs and materials allows vessels to withstand various challenges posed by their operating environments while ensuring both crew safety and sustainable practices in shipping operations across these beautiful archipelago waters.

Common Issues Faced by Ship Hulls in the Philippines

One of the most common issues faced by ship hulls in the Philippines is corrosion. The warm and humid climate, coupled with the presence of saltwater, creates an ideal environment for corrosion to flourish. As a result, shipowners often have to deal with rusting surfaces and weakened structural integrity. To combat this issue, regular inspections and maintenance routines are essential. Applying protective coatings and conducting thorough cleaning procedures can go a long way in preventing or mitigating corrosion damage.

Another major issue experienced by ship hulls in the Philippines is fouling from marine organisms such as barnacles and algae. These creatures attach themselves to the hull surface, increasing drag and reducing fuel efficiency. Not only does this result in higher operating costs for shipowners, but it also poses a threat to marine ecosystems as these organisms can be transported to different regions where they are not naturally found. To address this problem, anti-fouling coatings that inhibit the attachment of marine organisms can be applied to ship hulls. Additionally, routine maintenance should include proactive measures like regular cleaning and inspections underwater to prevent costly fouling-related issues down the line.

By understanding these common issues faced by ship hulls in the Philippines—corrosion and fouling—shipowners can prioritize effective maintenance strategies to ensure their vessels remain seaworthy while minimizing operation costs. Implementing preventive measures such as protective coatings, regular inspections, thorough cleanings, and employing anti-fouling technologies will help maintain optimal performance over the long term while protecting both ships and surrounding marine environments from the negative impacts of fouling. Protective coatings, such as anti-corrosion paints and specialized marine coatings, act as a barrier between the ship’s hull and the harsh seawater environment. These coatings not only prevent corrosion from damaging the hull but also make it difficult for fouling organisms to attach and grow.

Regular inspections play a crucial role in identifying any early signs of corrosion or fouling. This allows shipowners to take prompt action before these issues escalate into more significant problems.

The Importance of Ship Hull Maintenance in the Philippines

Ship hull maintenance is a critical aspect of the maritime industry in the Philippines. With its long coastline and reliance on shipping for trade, it is imperative for ship owners to prioritize keeping the hulls of their vessels in top condition. The saltwater environment can cause corrosion and damage to the hull, leading to potential leaks or structural issues. Regular inspections and maintenance work are necessary to ensure that ships remain seaworthy and can operate efficiently.

One key reason why ship hull maintenance is crucial in the Philippines is compliance with international regulations. The International Maritime Organization (IMO) sets standards for ship construction, including requirements for regular inspection and maintenance of vessel hulls. Failure to comply with these regulations could lead to penalties or even the detention of ships by port authorities. It is essential for ship owners in the Philippines to stay updated on these regulations, engage qualified professionals for inspections, and promptly address any identified issues.

In addition to regulatory compliance, proper ship hull maintenance also contributes to safety at sea. A well-maintained hull reduces the risk of accidents such as collisions or groundings by ensuring that the vessel remains structurally sound. Regular cleaning and anti-fouling measures help prevent barnacles and other marine organisms from accumulating on the hull, which can impact speed and maneuverability. By investing time and resources in maintaining ship hulls, both ship owners and crew members contribute to safer voyages across Philippine waters.

Ship hull maintenance plays a vital role in ensuring efficient operations while adhering to international standards and promoting safety in the Philippine Sea.

Common Issues with Ship Hulls in the Philippines

One common issue with ship hulls in the Philippines is corrosion. The humid and tropical climate, combined with the salty sea air, can greatly accelerate the rate of corrosion on a ship’s hull. This can lead to weakened structural integrity and increased maintenance costs. To combat this problem, regular inspections should be conducted, and any signs of corrosion should be promptly addressed through proper coating systems and anti-corrosion measures.

Another issue that ship owners often face in the Philippines is biofouling. The warm waters of the country provide an ideal breeding ground for marine organisms such as barnacles, seaweed, and algae to attach themselves to a ship’s hull. Not only does this negatively impact fuel efficiency by increasing drag, but it can also increase maintenance costs due to more frequent cleaning or even dry-docking for thorough removal. Implementing effective antifouling coatings can help prevent or minimize biofouling, reducing operational expenses in the long run.

By understanding these common issues with ship hulls in the Philippines and taking proactive steps towards prevention and maintenance, ship owners can ensure their vessels are well-maintained and optimized for performance in this unique maritime environment. With proper care and attention paid to combating corrosion and biofouling, ships operating in Philippine waters can remain seaworthy for longer periods while minimizing unnecessary downtime due to repairs or cleaning processes.

Here are the 4 secrets to ship hull maintenance in the Philippines:

1. Regular Cleaning and Inspection for Proper Ship Hull Maintenance in the Philippines

Regular cleaning and inspection are vital for proper ship hull maintenance in the Philippines. The country’s tropical climate and the harsh marine environment can quickly deteriorate a ship’s hull if not properly maintained. Regular cleaning involves removing algae, barnacles, and other marine growth that attach to the hull. This prevents corrosion and maintains the ship’s efficiency by reducing drag.

Shipowners in the Philippines must invest in regular cleaning and inspection as part of their overall maintenance strategy. Neglecting these essential tasks can have severe consequences for both safety and operational efficiency. By prioritizing regular cleaning and inspections, shipowners can ensure their vessels operate optimally while navigating Philippine waters’ unique challenges.

Importance of keeping the ship hull clean in the Philippines

One of the often overlooked aspects of ship maintenance is keeping the hull clean. In the Philippines, where pristine waters and vibrant marine life are abundant, it becomes even more crucial to prioritize this task. Not only does a clean ship hull improve fuel efficiency and performance, but it also helps protect the delicate ecosystems present in the country’s coastal areas.

The warm and tropical climate in the Philippines creates ideal conditions for biofouling to occur on ship hulls. When organisms such as barnacles, algae, and mollusks attach themselves to the hull, they create resistance that affects speed and fuel consumption. Regular cleaning not only prevents these organisms from smothering the hull but also saves money by reducing drag and increasing overall efficiency.

Furthermore, keeping the ship’s hull clean in this archipelago nation is crucial for maintaining biodiversity. The Philippines boasts an extraordinary range of marine life—from colorful coral reefs to rare marine species—that rely on healthy waters free from pollution and debris. By ensuring that ships operating in these waters have clean hulls, we can help preserve these fragile ecosystems for future generations to enjoy.

While many may overlook it as a mundane task, keeping a ship’s hull clean plays a vital role in sailing efficiently while protecting Philippine marine ecosystems’ well-being. By recognizing its importance and implementing regular cleaning practices, we can contribute to sustainable shipping practices that benefit both our economy and the environment simultaneously.

Tips for effective cleaning and inspection of vessels in the Philippines

When it comes to the effective cleaning and inspection of vessels in the Philippines, there are a few key tips that can make all the difference. First and foremost, regular cleaning is crucial to maintaining the integrity of a ship’s hull. This includes not only washing away dirt and debris but also removing any marine growth, such as barnacles, that may have attached themselves to the hull. By doing so, you can prevent these organisms from causing damage or increasing fuel consumption.

In addition to regular cleaning, conducting thorough inspections is equally important. This involves inspecting not just the external surfaces of the vessel but also the interior compartments for any signs of corrosion or structural damage. One useful technique is known as magnetic particle testing, which helps detect surface cracks and other defects that may not be visible to the naked eye. It’s also essential to pay attention to small details such as covers and seals on hatchways, ensuring they are secure and watertight.

By following these tips for effective cleaning and inspection, vessel owners in the Philippines can ensure their ships remain in top condition for extended periods of time. Not only does this help improve safety standards, but it can also lead to significant cost savings in terms of maintenance and repair expenses. Ultimately, taking proactive measures towards ship hull maintenance demonstrates a commitment to safe maritime practices while extending the lifespan of these valuable assets within Philippine waters.

2. Protective Coatings and Anti-fouling Systems for Proper Ship Hull Maintenance in the Philippines

Protective coatings and anti-fouling systems play a crucial role in the proper maintenance of ship hulls in the Philippines. With its vast coastline and extensive maritime activities, the country faces unique challenges when it comes to ship hull maintenance. The warm tropical climate, high humidity levels, and aggressive marine environment contribute to accelerated corrosion and fouling on hull surfaces.

Applying protective coatings helps prevent or mitigate corrosion by creating a barrier between the metal surface and the surrounding environment. These coatings are specially designed to withstand harsh marine conditions, including saltwater exposure, UV radiation, and abrasion from floating debris. Moreover, they increase the lifespan of ships by preventing structural damage caused by rusting and deterioration.

Anti-fouling systems are also essential for ship hull maintenance in Philippine waters. Fouling occurs when organisms such as barnacles, algae, mussels, and other aquatic microorganisms settle on the ship’s hull. This buildup not only impacts vessel performance but also increases fuel consumption due to added drag. Anti-fouling measures can include using biocidal paints that deter these organisms from settling or employing ultrasound technology that repels marine life without causing harm.

By investing in protective coatings and anti-fouling systems for ship hull maintenance in the Philippines, vessel owners can ensure greater operational efficiency, reduced fuel consumption, an extended equipment lifespan, and enhanced safety standards while complying with environmental regulations. Regular inspections followed by timely repairs or reapplications of these protective measures are crucial for maintaining optimal vessel performance in this challenging maritime environment.

Benefits of protective coatings on ship hulls in the Philippines

One of the key secrets to effective ship hull maintenance in the Philippines is the application of protective coatings. These coatings not only enhance the aesthetics of a ship but also provide numerous benefits that help extend its lifespan and ensure optimal performance. One significant advantage is corrosion prevention, as these coatings act as a barrier against harsh marine environments, preventing rust and deterioration.

Another benefit is enhanced fuel efficiency. Ship hulls that have been properly coated with anti-fouling paints experience less drag in the water, reducing resistance and improving speed. This results in lower fuel consumption and cost savings, making it an attractive investment for ship owners. Additionally, these coatings can also reduce maintenance costs by minimizing damage caused by fouling organisms such as barnacles and algae, which can hinder vessel operation.

Moreover, protective coatings on ship hulls offer environmental benefits. Anti-fouling paints contain biocides that deter marine growth while being environmentally safe to use. This helps prevent invasive species from attaching themselves to ships’ surfaces and spreading into sensitive ecosystems when ships sail between ports or regions. By utilizing these advanced technologies, ship owners in the Philippines are not only protecting their vessels but also taking crucial steps toward sustainable maritime practices.

Investing in protective coatings for ship hulls brings a myriad of benefits for both functionality and sustainability objectives. From corrosion prevention to improved fuel efficiency and eco-friendly operations, these coatings play a vital role in preserving ships’ longevity while reducing environmental impacts along Philippine waters- ultimately keeping the Philippine shipping industry ahead of its game on various global sustainability indices.

Different types of anti-fouling systems are available in the Philippines

There are several types of anti-fouling systems that can be used to maintain ship hulls in the Philippines. One common option is the ablative coating system, which works by slowly wearing away over time, releasing biocides to prevent marine growth. This type of system is effective for vessels that operate at varying speeds and in varying water conditions since the rate of wear adapts accordingly.

Another popular choice is the silicone-based anti-fouling system, which provides a smooth surface that prevents fouling organisms from adhering to the hull. Unlike ablative coatings, silicone-based systems do not wear away and require less frequent reapplication. These systems are ideal for ships with high-speed operations or vessels that spend extended periods in the water.

For those seeking an environmentally friendly option, there are also non-toxic anti-fouling systems available. These utilize advanced technologies such as ultrasonic waves or specialized coatings to prevent fouling without harming marine life or water quality. Although currently more expensive than traditional options, these eco-friendly solutions could become increasingly prevalent in Philippine waters as sustainability becomes a priority for maritime industries.

By being aware of the different types of anti-fouling systems available in the Philippines, shipowners and operators can make informed decisions to protect their vessel’s hull while minimizing environmental impact. Whether it be using abrasion-resistant coatings suitable for varying conditions or adopting cutting-edge technologies, implementing an effective anti-fouling strategy is crucial for long-term maintenance success in this archipelagic nation’s waters.

3. Vessel Repairing and Preventing Corrosion in the Philippines

When it comes to vessel repair and preventing corrosion in the Philippines, there are a few key factors to consider. First and foremost, there is the importance of regular maintenance and inspection. Vessels that navigate the waters of the Philippines are exposed to various environmental factors that can contribute to corrosion, such as saltwater and high humidity levels. By implementing a comprehensive maintenance plan that includes routine inspections, repairs, and protective measures, ship owners can prolong the lifespan of their vessels.

In addition to regular maintenance, another crucial aspect of preventing corrosion is selecting the right materials for construction or repair work. Choosing high-quality materials that are specifically designed for marine environments can make a significant difference in preventing corrosion-related issues. This includes using anti-corrosive coatings, paints, and other protective measures that are specially formulated for maritime applications. Investing in these materials may require an upfront cost but can save ship owners from expensive repairs and replacements down the line.

Lastly, collaboration between ship owners, crew members, and industry experts plays a crucial role in vessel repair and preventing corrosion. By working together with trusted professionals who have experience in maritime engineering and hull integrity management, ship owners can gain valuable insights into best practices for maintaining their vessels’ structural integrity. Regular training for crew members on identifying early signs of corrosion or damage is also essential so that issues can be addressed promptly before they worsen.

Ship repair in Tanza, Cavite, and preventing corrosion of vessels in the Philippines require a proactive approach involving regular maintenance, selecting appropriate materials, and collaboration with Filipino industry experts. With these strategies in place, ship owners can ensure that their vessels are in optimal condition and minimize the risk of accidents or breakdowns at sea.

Identifying and addressing corrosion on the ship hull in the Philippines

When it comes to ship hull maintenance in the Philippines, one of the most critical issues that ship owners and operators must address is corrosion. Being located in Southeast Asia, the Philippines experiences a tropical climate with high humidity and saltwater exposure, making ships prone to corrosion. Identifying early signs of corrosion is crucial to preventing further damage to the ship’s structure and components.

One technique for identifying corrosion on the ship’s hull is regular visual inspections. These inspections should be conducted by trained professionals who can recognize signs such as rusting patches or discoloration on the hull surface. In addition to visual inspections, non-destructive testing methods like ultrasonic thickness measurement can also be employed to identify hidden areas of corrosion.

Once identified, addressing corrosion on the ship’s hull requires a systematic approach. Repairing small areas of localized corrosion may involve removing any loose paint or rust using abrasive techniques and applying protective coatings specifically designed for marine environments. For larger areas of extensive damage, sections of corroded steel may need replacement through welding or other repair methods.

By diligently identifying and addressing corrosion on their ship’s hull, Filipino operators can extend their vessel’s lifespan while ensuring safe operations at sea.

Overall, proactive monitoring and timely repairs are key secrets to effective ship hull maintenance amidst the challenging conditions prevalent in this region.

Techniques to prevent future corrosion damage to vessel hulls in the Philippines

One of the most effective techniques to prevent future corrosion damage to ship hulls in the Philippines is through proper protective coating application. Using high-quality coatings that are specifically designed for marine environments can significantly prolong the lifespan of a ship’s hull. These coatings act as a barrier, shielding the metal from exposure to corrosive elements, such as salt water and pollutants. Regular inspections and touch-ups should also be conducted to ensure that any areas where the coating may have worn off are promptly addressed.

Another technique that has gained popularity in recent years is cathodic protection. This method involves installing sacrificial anodes on a ship’s hull, which are then connected to its metal structure. The anodes corrode instead of the hull, effectively sacrificing themselves to protect the vessel from corrosion damage. Cathodic protection systems require regular monitoring and ship hull maintenance, but they offer long-term benefits in terms of reducing maintenance costs and ensuring better vessel longevity.

By implementing these proactive techniques, ship operators can greatly minimize the risk of corrosion damage to their vessels’ hulls in the Philippines’ harsh maritime environment. With proper protective coatings and a well-maintained cathodic protection system in place, ships can navigate waters with confidence and extend their service life while minimizing downtime due to repairs. Investing time and resources into preventive measures today will lead to significant cost savings tomorrow while ensuring safer voyages for both crew and cargo alike.

4. Properly Maintaining Ballast Tanks and Bilges of Vessels in the Philippines

Properly maintaining ballast tanks and bilges as part of ship hull maintenance is vital for ensuring the overall integrity and longevity of a ship’s hull. In the Philippines, a country surrounded by sea, where maritime activities play a significant role in its economy, this task becomes even more critical. Neglecting proper maintenance can lead to costly repairs or, worse, resulting in accidents and environmental hazards.

With the ever-increasing regulations on environmental protection, it is crucial for shipowners in the Philippines to understand the importance of regular inspections and cleaning of their ballast tanks and bilges. These areas are prone to corrosion caused by saltwater exposure, as well as the buildup of sediments and harmful substances. By implementing effective maintenance practices such as regular inspections, tank cleaning procedures, and anti-corrosion measures, shipowners can mitigate potential risks while extending the lifespan of their vessels.

Moreover, incorporating advanced technologies like remote sensing devices or automation systems into vessel maintenance operations can significantly improve efficiency and accuracy. These technologies allow for real-time monitoring of tank conditions, enabling early detection of any issues, such as leaks or contamination. By investing in these innovative solutions, ship operators not only enhance safety but also streamline maintenance processes on their vessels operating within Philippine waters, ultimately making them more competitive in an increasingly globalized maritime industry.

The Best Ship Hull Maintenance Company in the Philippines?

When it comes to ship hull maintenance in the Philippines, there is one company that stands out among the rest: Amaya Dockyard & Marine Services Inc. (ADMSI). With its commitment to providing quality and cost-effective services, ADMSI has earned its reputation as the best ship hull maintenance company in Tanza, Cavite, Philippines.

- Email us: info@amayadockyard.com

- Call our 24-hour hotline: +63 917 633 0479

- Viber: +63 917 633 0479

- WhatsApp: +63 917 633 0479

- Facebook Messenger: Click here

- Click here to inquire

One of the key factors that sets ADMSI apart from its competitors is its team of highly skilled and experienced professionals. Their technical expertise allows them to tackle even the most complex ship hull maintenance projects with ease. From surface preparation and coating application to corrosion control and structural repairs, ADMSI ensures that every aspect of ship hull maintenance is carried out flawlessly.

What truly makes ADMSI exceptional is its dedication to providing cost-effective solutions without compromising on quality. They understand that ship owners need reliable services at competitive prices, which is why they continuously strive for efficiency in their processes. By employing innovative techniques and utilizing state-of-the-art equipment, ADMSI maximizes productivity while minimizing costs—a win-win situation for both them and their clients.

For anyone looking for top-notch ship hull maintenance services in the Philippines, Amaya Dockyard & Marine Services Inc. should be at the top of their list. With a team of skilled professionals committed to delivering quality workmanship at affordable prices, ADMSI has established itself as a leader in this industry. Trust them with your vessel’s upkeep needs, and you can rest assured that it will be performed with utmost excellence and attention to detail. ADMSI understands the importance of maintaining a ship’s hull to ensure its longevity and optimal performance. Their team is equipped with the latest technology and tools, allowing them to carry out inspections, repairs, and maintenance tasks efficiently.

Whether it’s routine cleaning, painting, or more complex repair work, ADMSI has the expertise to handle it all. They follow strict industry standards and adhere to safety regulations at every step of the process.

The Role of Technology in Ship Hull Maintenance in the Philippines

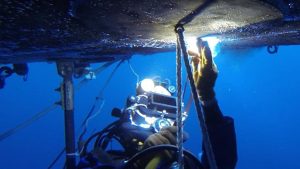

Gone are the days when ship hull maintenance in the Philippines relied solely on traditional methods. The advent of technology has revolutionized this crucial aspect of the maritime industry, bringing about faster and more efficient ways to keep ship hulls in optimal condition. One such technology is underwater drones equipped with high-resolution cameras that can capture detailed images of the hull.

These remotely operated vehicles (ROVs) allow inspectors to assess the state of a ship’s hull without having to dry dock it, saving time and money. By using ROVs, inspection teams can quickly identify any defects or corrosion in the hull and take immediate action. Additionally, advanced imaging software can analyze these images to detect even minor cracks or damages that might be invisible to the naked eye. As a result, shipowners and operators can address issues promptly before they escalate into major problems.

Another technological advancement making waves in ship hull maintenance is artificial intelligence (AI). AI algorithms can process vast amounts of data gathered from various sources, like weather forecasts, historical performance records, and sensor readings. This information allows AI-powered systems to predict possible maintenance needs accurately. With predictive analytics at their disposal, ship operators can plan for repairs or maintenance activities ahead of time, reducing unexpected downtime and maximizing vessel availability for charter or cargo transportation.

The role of technology in ship hull maintenance cannot be overstated. From underwater drones providing detailed inspections without dry docking to AI-powered predictive analytics identifying potential issues before they occur, these advancements have transformed how ships are maintained in the Philippines and beyond.

Takeaway: 4 Secrets to Ship Hull Maintenance in the Philippines

In conclusion, ship hull maintenance in the Philippines is a crucial aspect of ensuring the longevity and performance of a vessel. By understanding the secrets to effective maintenance, ship owners and operators can save costs, reduce downtime, and avoid potential hazards—the first secret lies in proactive inspections and regular cleaning. By conducting thorough inspections and keeping the hull clean from biofouling, ships can maintain smooth surfaces that enhance fuel efficiency and prevent damage.

The second secret is to prioritize protective coatings. Applying high-quality coatings to the ship’s hull not only protects it from corrosion but also improves its hydrodynamics. With advanced coating technology available today, it is crucial for ship owners to invest in products that offer longer protection intervals while providing environmental benefits.

Thirdly, proper care must be given to sacrificial anodes, small pieces of metal placed on or near the hull to protect against galvanic corrosion. Regular inspection and replacement ensure optimal protection for the entire vessel.

Lastly, staying informed about industry developments is essential. Technology advancements are constantly being made in ship hull maintenance, such as new methods of cleaning or innovative coating solutions. By staying up-to-date with these developments through industry conferences or education platforms, shipping companies can continuously enhance their maintenance practices.

By following these four secrets to ship hull maintenance in the Philippines—proactive inspections, prioritizing protective coatings, caring for sacrificial anodes, and staying informed about industry developments—vessels can navigate Philippine waters with confidence and efficiency while ensuring optimal performance throughout their lifespan.