In the vast expanse of the world’s oceans, ship propellers serve as the unsung heroes that propel vessels through turbulent waters. However, these vital components are not immune to wear and tear, often requiring prompt repairs to ensure smooth sailing. For shipowners and operators seeking top-notch maintenance services for their valuable fleets, the Philippines emerges as an unexpected yet promising destination. With its rich maritime heritage and a burgeoning industry dedicated to ship propeller repair in the Philippines, this ultimate guide will navigate you through the intricacies of finding reliable repair facilities, skilled technicians, and cost-effective solutions in this archipelagic nation. From bustling ports to hidden gems tucked away in idyllic coastal towns, explore how the Philippines is revolutionizing ship propeller repair with unparalleled expertise and an unwavering commitment to excellence.

Click here to view our ship propeller repair services in Tanza, Cavite, Philippines.

The Importance of Ship Propeller Repair in the Philippines

Ship propeller repair in the Philippines plays a crucial role in maintaining the efficiency and performance of vessels within the maritime industry. With its extensive coastline and dependence on maritime trade, the country relies heavily on ships for the transportation of goods and people. However, with constant use and exposure to harsh marine conditions, ship propellers are prone to wear and damage over time.

By prioritizing ship propeller repair in the Philippines, vessel operators can ensure that their ships operate at maximum efficiency, reducing fuel consumption and minimizing environmental impact. Moreover, regular maintenance of propellers can extend their lifespan while preventing costly downtime due to unexpected breakdowns. Given that shipping is a major contributor to global greenhouse gas emissions, efficient ship propagation is essential for sustainability.

The Philippines has positioned itself as a leading hub for ship propeller repair in Southeast Asia. With highly skilled technicians and advanced facilities catering specifically to the needs of maritime industry players, local repair services offer excellent value for money while adhering to international safety standards. Furthermore, by investing in ship propeller repair infrastructure locally, the Philippines not only supports its own economy but also attracts foreign vessel owners who seek cost-effective solutions without sacrificing quality.

Ship propeller repair in the Philippines is an integral part of ensuring smooth operations in the maritime industry. By recognizing its importance as a means to improve efficiency and reduce environmental impact while supporting local economic development, vessel operators have much to gain from regularly maintaining their vessels’ propellers.

Understanding the Basics of Vessel Propellers

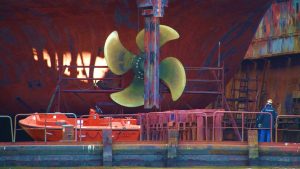

The ship propeller is a critical component of any vessel, responsible for generating the thrust necessary to move the ship through the water. Understanding its basics is essential for ship owners and operators to ensure optimal performance and minimize downtime due to propulsion issues.

At its core, a ship propeller consists of multiple blades mounted on a rotating hub. The shape and size of these blades affect the efficiency and power output of the propeller. The most common type is the fixed-pitch propeller, where the blade angle cannot be changed during operation. On the other hand, variable-pitch propellers allow for adjusting blade angle to optimize performance at different speeds or load conditions. Another variation is controllable pitch propellers, which enable changing blade angles even while underway.

It’s important to note that factors such as hull design, engine power, speed requirements, and vessel size all influence which type of ship propeller should be used. Ensuring proper selection and maintenance plays a vital role in achieving fuel efficiency goals and maximizing overall operational effectiveness. By understanding the basics of ship propellers, both naval architects and ship owners can make informed decisions when it comes to repair or replacement options for their vessels’ propulsion systems.

Common Causes of Ship Propeller Damage in the Philippines

Ship propeller damage can have a significant impact on a vessel’s performance and efficiency. Understanding the causes of propeller damage is crucial in preventing maintenance issues and costly repairs. One common cause of damage is cavitation, which occurs when water pressure decreases rapidly around the propeller blades. This can lead to pitting and erosion, reducing the effectiveness of the propeller. Another cause is impact damage from debris or collisions with underwater objects. Even small dents or scratches can disrupt the flow of water around the propeller, diminishing its efficiency.

To address ship propeller damage, regular inspections and maintenance are essential. This includes monitoring for signs of cavitation or impact damage during routine drydocking periods, as well as conducting underwater inspections using remote-operated vehicles (ROVs) or divers equipped with high-resolution cameras. Prompt repair of any identified damages will help ensure optimal performance and reduce the risk of further deterioration.

Investing in advanced technologies, such as composite materials for propellers, can also help minimize corrosion and improve durability. These lightweight materials not only increase fuel efficiency but also provide better resistance against cavitation and impact damage. Furthermore, ongoing research into innovative coatings and design modifications continues to push boundaries in increasing lifespan while reducing maintenance requirements.

By understanding the causes of ship propeller damage, performing regular inspections, investing in advanced technologies, and staying informed about industry advancements, ship owners and operators can proactively manage their vessels’ propulsion systems to maximize efficiency while minimizing downtime due to repairs or replacement components.

1. Corrosion: Ship Propeller Repair in the Philippines

Corrosion is a major concern when it comes to ship propeller repair in the Philippines. With its tropical climate and vast coastline, the country is highly susceptible to corrosion caused by constant exposure to seawater. This poses challenges for ship owners and maintenance crews, as they must find effective ways to combat corrosion and prolong the life of their vessels’ propellers.

One innovative approach that has gained popularity in recent years is the use of advanced coatings. These coatings act as a barrier between the metal surface of the propeller and the corrosive elements in seawater. By applying these protective coatings, ship owners can significantly reduce the rate of corrosion and extend the lifespan of their propellers. Additionally, these coatings can also improve fuel efficiency by reducing friction between water and propeller blades.

Apart from using advanced coatings, regular maintenance procedures play a crucial role in preventing corrosion on ship propellers. This includes proper cleaning and inspection to identify early signs of damage or wear that could potentially lead to corrosion. In some cases, repairs may be necessary, such as filling pits with epoxy resin or even replacing damaged sections of the propeller entirely. Ship owners must prioritize routine maintenance checks to ensure their propellers are in excellent condition throughout their lifespan.

Addressing corrosion concerns during ship propeller repair in the Philippines requires a proactive approach that combines effective protective measures like advanced coatings with regular maintenance practices. By implementing these strategies, ships operating in Philippine waters can minimize downtime due to repairs while ensuring safe and efficient navigation for years to come.

2. Cavitation: Ship Propeller Repair in the Philippines

Ship propeller repair in the Philippines is a vital part of ensuring efficient and smooth sailing for ships. Cavitation occurs when the pressure on a ship’s propellers drops below the vapor pressure of water, leading to the formation of vapor bubbles that collapse with tremendous force. This collapsing action can cause significant damage to propellers, leading to decreased performance and increased fuel consumption.

In the Philippines, ship propeller repair facilities have developed advanced techniques and technologies to address cavitation-related issues effectively. One such technique is using specialized coatings that provide better protection against cavitation erosion. These coatings act as barriers between the propellers and water, reducing the impact of bubble collapse and prolonging their lifespan.

Furthermore, vessel repair facilities in the Philippines employ skilled technicians who are well-versed in repairing damaged propellers caused by cavitation. They have access to specialized equipment and tools needed for precise repairs, ensuring that any damages are addressed promptly and efficiently. By regularly inspecting and maintaining ship propellers susceptible to cavitation damage, vessels can experience enhanced performance while minimizing costly downtime.

Ship propeller repair in the Philippines highlights the importance of addressing cavitation issues promptly and effectively through advanced techniques such as protective coatings and skilled repairs.

3. Impact and Collision Damage: Ship Propeller Repair in the Philippines

Impact and collision damage to ship propellers can have serious consequences, not only for the vessel itself but also for crew safety and the environment. In the Philippines, ship propeller repair services provide crucial support in mitigating the effects of such incidents. These repair facilities are equipped with state-of-the-art technology and highly skilled technicians who are able to assess the extent of damage, identify weak points in the propeller structure, and carry out necessary repairs efficiently.

One key aspect that sets ship propeller repair in the Philippines apart is its focus on using advanced materials for repairs. By utilizing high-quality alloys and composites specifically designed for marine applications, these repair facilities ensure that repaired propellers are durable and resistant to future impact or collision damage. This not only enhances the overall operational efficiency of vessels but also contributes to environmental sustainability by reducing downtime due to frequent repairs or replacements.

Furthermore, ship propeller repair facilities in Tanza, Cavite, such as Amaya Dockyard & Marine Services Inc. (ADMSI), offer comprehensive inspection services to assess potential hidden damages caused by impacts or collisions. Advanced scanning techniques like ultrasonic testing and magnetic particle inspections help detect even minute cracks or weaknesses in propeller blades, which may lead to catastrophic failures if left unattended. By proactively identifying such issues during routine inspections, these facilities play a critical role in preventing costly accidents at sea.

Ship propeller repair services in Manila, Cebu, Zambales, Navotas, Batangas, and Cavite provide essential expertise in addressing impact and collision damage. Through their use of advanced materials and thorough inspection techniques, they contribute to enhancing vessel safety, operational efficiency, and environmental sustainability.

4. Fouling: Ship Propeller Repair in the Philippines

Fouling, the accumulation of marine organisms on ship propellers, is a common issue faced by ships sailing in the Philippines. The warm tropical waters and abundant marine life provide an ideal environment for fouling to occur. This not only affects the efficiency of the propeller but also increases fuel consumption and maintenance costs for ship owners.

In recent years, there has been a growing interest in developing eco-friendly solutions to combat fouling. Traditional methods, such as chemical coatings, have proven to be harmful to marine ecosystems and are now being phased out. Instead, new technologies like ultrasonic antifouling systems are gaining popularity due to their effectiveness in preventing fouling without causing harm to the environment.

One innovative approach being explored in the Philippines is the use of biological antifouling agents derived from native marine species. Researchers have discovered certain compounds that possess natural anti-fouling properties, offering a more sustainable alternative to traditional methods. By harnessing nature’s own defenses against fouling, these agents have shown promising results in significantly reducing biofouling on ship propellers.

Finding effective solutions for fouled ship propellers is not only crucial for maintaining optimal vessel performance but also contributes to preserving fragile marine ecosystems. The ongoing research and development efforts being undertaken in the Philippines hold great promise for both the shipping industry and environmental conservationists alike.

5. Poor Maintenance Practices: Ship Propeller Repair in the Philippines

Poor maintenance practices when it comes to ship propeller repair in the Philippines can have severe consequences for both the ship owners and the environment. Neglecting regular maintenance and opting for quick fixes or temporary solutions may seem cost-effective in the short term, but it can lead to major damages down the line. Corroded propellers, unbalanced blades, and worn-out components not only decrease a ship’s efficiency but also increase fuel consumption and emissions.

Furthermore, poor maintenance practices can result in unexpected breakdowns at sea, risking the lives of crew members and causing disruptions in shipping schedules. It is essential for ship owners to prioritize proper propeller maintenance to avoid these risks. By investing in regular inspections, cleaning, polishing, and repairs by certified professionals, ship owners can ensure the optimal performance of their vessels while minimizing environmental impacts.

However, improving maintenance practices goes beyond individual efforts; it requires collaboration between ship owners, regulators, and service providers. Strengthening regulations around propeller maintenance standards can help prevent subpar repair work while encouraging industry-wide compliance with best practices. Additionally, raising awareness about the importance of proper maintenance among all stakeholders involved will foster a culture of proactive care for both ships and the marine environment in which they operate.

Finding a Reliable Ship Propeller Repair Company in the Philippines

In the bustling maritime industry, keeping ships in top condition is crucial for smooth operations and optimal performance. One of the critical components that requires regular maintenance and repair is the ship propeller. However, finding a reliable ship propeller repair company can be challenging, especially with numerous options available in the Philippines. Among these choices is Amaya Dockyard & Marine Services Inc. (ADMSI), an established player in the industry that offers cost-effective and quality solutions.

- Email us: info@amayadockyard.com

- Call our 24-hour hotline: +63 917 633 0479

- Viber: +63 917 633 0479

- WhatsApp: +63 917 633 0479

- Facebook Messenger: Click here

- Click here to inquire

What sets ADMSI apart from other ship propeller repair companies in the Philippines? Firstly, their extensive experience and expertise make them a trusted choice among ship owners and operators. With years of hands-on involvement in various maritime projects, ADMSI has honed its skills in repairing different types of ship propellers efficiently. Their dedicated team of professionals knows how to handle complex repairs using state-of-the-art equipment and techniques to ensure that ships are back on track as quickly as possible.

Additionally, ADMSI prides itself on its commitment to quality assurance. The company follows strict standards and procedures throughout the entire repair process to consistently deliver exceptional results. From initial assessment to final inspection, every step undergoes meticulous scrutiny to guarantee that each repaired ship propeller meets or exceeds industry standards.

Finding a reliable ship propeller repair company in the Philippines may seem confusing for Filipino boat and vessel owners; however, by selecting Amaya Dockyard & Marine Services Inc., you can trust that your vessel will receive cost-effective repairs without compromising on quality or efficiency.

The Process of Ship Propeller Repair

Ship propeller repair in the Philippines is often overlooked when it comes to ship maintenance, but it plays a crucial role in ensuring the efficient operation of vessels. A damaged or worn-out propeller can lead to increased fuel consumption, decreased maneuverability, and even potential accidents at sea. By investing in regular propeller repair and maintenance, ship owners and operators can save money in the long run by reducing fuel costs and avoiding costly repairs or replacements.

In addition to saving money, proper propeller repair also helps reduce emissions and make shipping more sustainable. A well-maintained propeller improves fuel efficiency, which directly translates into lower greenhouse gas emissions. With the global shipping industry facing pressure to reduce its environmental footprint, investing in ship propeller repair in the Philippines is not only economically wise but also environmentally responsible.

Moreover, ship propeller repair in the Philippines is not just about fixing damages; it also presents an opportunity for performance enhancement. Propellers can be re-profiled or modified during the repair process to optimize their performance based on specific vessel requirements. This allows ships to achieve higher speed capabilities with less power input or improve maneuverability for safer navigation in challenging conditions. By understanding the importance of ship propeller repair in the Philippines as not just a necessary maintenance task but also an opportunity for optimization, ship owners can further enhance their vessels’ operational efficiency and overall performance.

Ship propeller repair in the Philippines should be viewed as a vital aspect of responsible ship management that goes beyond mere fixes.

Here is the step-by-step ship propeller repair process in the Philippines:

Step 1: Inspection and assessment of damage

The inspection and assessment of damage is a crucial first step in the ship propeller repair process in the Philippines. It involves a thorough examination of the propeller to identify any signs of wear, erosion, cracks, or other forms of damage. This initial inspection not only helps determine the extent of the problem but also allows for an accurate estimation of repair costs and timeframes.

During this stage, experienced technicians use various tools and techniques to inspect every aspect of the propeller carefully. Advanced technologies like ultrasound testing may be employed to detect hidden flaws that are not visible to the naked eye. The assessment also includes assessing the overall condition of the propeller shaft and other associated components.

By conducting a comprehensive inspection and assessment, ship owners can make informed decisions about repairing or replacing their damaged propellers. This step sets the foundation for successful repairs by providing valuable insights into the scope and complexity of the required work. Additionally, it ensures that all potential damage is identified upfront, eliminating any surprises during later stages of repair or in-service operation.

Step 2: Removal of the damaged propeller

One of the most crucial steps in ship propeller repair is the removal of the damaged propeller. This process requires careful planning and execution to ensure the safety of personnel and prevent any further damage to both the vessel and the propeller itself.

To start, specialized equipment such as cranes or hydraulic jacks is often used to lift the ship’s stern out of water, allowing access to the propeller. This step alone can be quite challenging due to logistical constraints and varying weather conditions. Once access is gained, divers will then need to inspect and assess the extent of damage to the propeller blades.

But removing a damaged propeller isn’t simply a matter of unbolting it from its shaft. It requires skillful coordination between divers, engineers, and other crew members involved in dismantling this massive component underwater. The use of cutting tools may be necessary, but the utmost care must be taken not to damage surrounding structures or cause any harm to marine life.

This meticulous ship repair process highlights how expertise and precision play crucial roles in efficient propeller removal during ship repairs.

Step 3: Cleaning and preparation for repair

Now that the ship’s propeller has been safely removed, it’s time to focus on cleaning and preparing it for repair. Cleaning is an essential step in the process, as it helps remove any dirt, rust, or debris that may have accumulated over time. One effective method is using a high-pressure washer to blast away grime and ensure a clean surface for further inspection.

Once the propeller is clean, thorough preparation is required before starting any repair work. This involves carefully examining the propeller for any signs of damage or wear, such as cracks, chips, or erosion. It’s crucial to address these issues promptly to prevent further damage or compromise the performance of the ship’s propulsion system.

During this stage of preparation, precise measurements are taken to determine the extent of repair needed. Specialized equipment like digital scanning devices may be used to accurately assess the condition of each blade and gather data for generating a detailed analysis report. These measurements are vital in order to identify specific areas where repairs will be carried out and ensure optimal balance once completed.

Cleaning and preparing a ship’s propeller for repair in the Philippines requires meticulous attention to detail.

Step 4: Repairing the damaged propeller

Now that we have identified the extent of damage and cleaned the ship propeller, it is time to move on to the crucial step of repairing it. The repair process involves various intricate procedures that require expertise and precision. One common method used for repairing a damaged propeller is welding. Skilled welders carefully rebuild areas where blades may have been broken off or bent out of shape. This ensures that the propeller retains its balance and efficiency in generating thrust.

Another important aspect of repairing a damaged propeller is surface finishing. After any necessary welding work has been completed, the propeller needs to be restored to its original smooth and polished condition. Technicians employ advanced techniques such as grinding, sanding, and polishing to eliminate any imperfections or rough surfaces on the blades. This ensures optimal hydrodynamic performance by reducing drag and turbulence caused by an uneven surface.

Repairing a damaged ship’s propeller requires expertise in both engineering and metallurgy. It is vital for technicians involved in this process to understand not only how each component functions but also how they interact with one another as a whole system. By carefully assessing the damage, using appropriate repair methods like welding, and ensuring proper surface finishing, technicians can restore a damaged ship’s propeller to its full functionality for safe navigation at sea.

Step 5: Balancing and testing the repaired propeller

Balancing and testing the repaired propeller is a crucial step in the ship propeller repair process in the Philippines. After all, a balanced propeller ensures smooth operation and reduces vibration, leading to enhanced fuel efficiency and overall performance.

To begin with, balancing the repaired propeller involves removing any excess material or adding weight as necessary to ensure it is evenly distributed. This process can be achieved through various methods, such as dynamic balancing or static balancing. Dynamic balancing involves spinning the propeller while measuring its vibrations, allowing technicians to identify any imbalances and correct them accordingly. On the other hand, static balancing involves suspending the propeller and using weights to counterbalance any heaviness on one side.

Once the propeller has been balanced, it is essential to conduct thorough testing before reinstallation. This ensures that all repairs have been successfully completed without any further issues. Testing typically includes running simulations in controlled conditions that mimic real-life operating scenarios. By monitoring factors such as speed, noise levels, vibrations, and water flow patterns during these tests, technicians can detect any potential problems before they become critical and make adjustments if needed.

Balancing and testing a repaired ship propeller is an integral part of ensuring optimal performance for marine vessels. Carefully examining for balance issues post-repairing work and conducting thorough evaluations under simulated conditions through rigorous testing procedures helps prevent future breakdowns or inefficiencies at sea, ultimately increasing safety measures onboard!

Tips for Maintaining and Extending the Lifespan of Propellers in the Philippines

To ensure the smooth and efficient operation of ships, it is crucial to maintain and extend the lifespan of propellers properly. The harsh marine environment in the Philippines can take a toll on these vital parts, but with proper care and attention, it is possible to keep them in excellent condition for longer.

Firstly, regular cleaning is essential to prevent fouling and corrosion. Marine growth can significantly impact the performance of propellers and increase fuel consumption. By regularly removing any accumulated barnacles or algae from the blades, ship owners can improve efficiency and ensure optimal propulsion.

Additionally, investing in high-quality coatings can provide an extra layer of protection against corrosion. The Philippines, being a tropical country with warm waters, creates favorable conditions for rusting and degradation. Applying a durable coating that resists marine fouling and electrolysis will help maximize the propeller lifespan.

Lastly, monitoring vibration levels during operation can be an effective way to identify any potential issues early on. Excessive vibration may indicate an imbalance or damage within the propeller system. Regular inspections by certified technicians who specialize in ship propeller repair in the Philippines should be scheduled to address these concerns promptly.

By following these tips for maintaining and extending the lifespan of ship propellers in the Philippines, vessel operators can minimize downtime, reduce repair costs, and optimize overall performance at sea.

Cost and Time Implications of the Ship Propeller Repair Process in the Philippines

When it comes to ship propeller repair in the Philippines, there are two crucial factors that every ship owner or operator needs to consider: cost and time. The repair process itself can be quite expensive, depending on the extent of the damage and the expertise required for the repairs. Not only do you have to cover the cost of labor and materials, but you may also need to factor in additional expenses, such as dry docking fees or transportation costs, if your vessel needs to be taken out of the water for repairs.

Moreover, time is of utmost importance in the shipping industry. Every day that a vessel is out of commission for repairs can result in significant financial losses. Therefore, it is essential to find a repair facility that can efficiently carry out the necessary repairs within a reasonable timeframe. This means finding a highly skilled team of technicians and welders who can work quickly without compromising on quality.

Considering both cost and time implications is crucial when deciding on where to get your ship’s propeller repaired. A balance must be struck between finding an affordable solution without sacrificing quality or efficiency. By doing thorough research and considering various options, you can ensure that your ship propeller repairs are conducted seamlessly while minimizing downtime and maximizing cost efficiency.

Takeaway: Ultimate Guide to Ship Propeller Repair in the Philippines

In conclusion, ship propeller repair in the Philippines presents a myriad of opportunities and challenges for maritime industries. With its strategic location, abundant skilled workers, and cost-effective services, the Philippines has become a preferred destination for shipowners seeking reliable propeller repair solutions.

However, it is crucial to consider certain factors when choosing a propeller repair service provider in the country. Apart from technical expertise and equipment capabilities, one should also evaluate their track record of delivering quality repairs within the agreed timeframe. Additionally, assessing their commitment to environmental sustainability initiatives can benefit both business operations and the preservation of marine ecosystems.

Ultimately, with careful consideration and due diligence, ship owners can confidently entrust their vessel’s propeller repair needs to reputable service providers in the Philippines. This guide aims to equip readers with the essential information necessary for making informed decisions that will ensure efficient operations and maximum productivity while maintaining environmental responsibility.