Vessel ballast tanks may not be the most glamorous or talked-about features of ships in the Philippines, but they play an essential role in ensuring the stability and safety of these colossal structures that navigate our oceans. These often overlooked watertight compartments serve as temporary reservoirs for water or other substances, helping to maintain balance, adjust draft levels, and improve maneuverability. Whether you’re a maritime enthusiast seeking a deeper understanding of ship design, an aspiring Filipino seafarer looking to grasp the fundamentals of vessel operations, or simply curious about how these gigantic vessels stay afloat, this ultimate guide to vessel ballast tanks will take you on an enlightening voyage into the fascinating world beneath the waves. From their history and types to their crucial functions and maintenance protocols, prepare to dive deep into the mysteries of vessel ballast tanks in the Philippines!

Click here to read about our vessel ballast tanks and ship repair services in Tanza, Cavite, Philippines.

Understanding the Purpose of Vessel Ballast Tanks

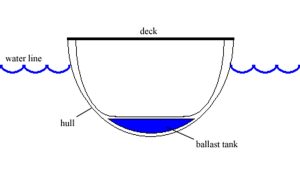

Vessel ballast tanks may seem like a mundane and unnoticed part of a ship, but their purpose is integral to the smooth operation and stability of any vessel. These tanks are designed to control the weight distribution within a ship, ensuring proper balance and stability in various conditions in the Philippine Sea.

Ballast tanks on ships play a crucial role in vessels by providing additional weight or buoyancy as required. They can be filled with water or emptied through complex systems, allowing ships to adjust their center of gravity when needed. This helps prevent excessive rolling or pitching, especially during rough weather or when carrying uneven loads. By strategically distributing weight throughout the ship, ballast tanks ensure better maneuverability and reduce stress on the hull, ultimately enhancing safety for crew members and cargo alike.

Understanding the purpose of vessel ballast tanks is important not only for those working on board but also for anyone involved in shipping operations. The ability to properly manage ballast can significantly impact fuel efficiency and operating costs. When properly employed, vessel ballast tanks minimize resistance against ocean currents, optimize speed and draft levels, as well as enhance propulsion performance by improving trim and stability characteristics.

In conclusion, vessel ballast tanks serve more than just an ancillary role in maritime operations – they are essential for maintaining equilibrium at sea. Their intricate functions allow ships to adapt to varying conditions while ensuring the safety of crew members and cargo assets. Additionally, understanding their purpose can lead to significant cost savings through improved fuel efficiency management strategies.

Importance of Proper Ballasting for Ship Stability

Proper ballasting is crucial for maintaining ship stability and ensuring safe navigation in the Philippines. The ballast tanks of a boat play a critical role in achieving this balance. These tanks are filled with water or other materials to counteract the weight of cargo, equipment, and fuel, preventing the ship from capsizing or listing excessively.

One key aspect of proper ballasting is adjusting the weight distribution as cargo is loaded or discharged. This dynamic process requires careful monitoring and calculations to ensure the vessel remains stable throughout its journey. Improper ballasting can lead to a range of issues, including excessive bending moments and shear forces on the hull structure, which can compromise the safety and integrity of the entire ship.

Furthermore, proper ballasting also influences a ship’s fuel efficiency. By optimizing weight distribution through precise ballast management, vessel owners can reduce drag and resistance in the water, thereby enhancing overall performance and decreasing fuel consumption. In an era where energy efficiency is paramount for sustainability reasons as well as economic viability, this aspect cannot be overlooked.

Understanding and implementing proper ballasting techniques is not just about compliance with maritime regulations; it directly affects ship stability, safety at sea, structural integrity, and fuel efficiency. It demands meticulous attention to detail from shipowners and crew members alike throughout every voyage. Investing in advanced technologies such as automated ballast control systems enables real-time monitoring and adjustment capabilities that further enhance these aspects while reducing human error risks – ultimately leading to safer voyages for seafarers worldwide.

Types of Vessel Ballast Tanks Commonly Found in the Philippines

The Philippines is home to a diverse fleet of vessels, each with its own unique ballast tank configuration. One of the most common types found in these vessels is the double-bottom tank. As its name suggests, this type of tank is located at the bottom of the ship’s hull, providing stability and supporting cargo loads. It is typically divided into several compartments to ensure even weight distribution and better control over ballasting operations.

Another common ballast tank found in Philippine vessels is the wing tank. These tanks are horizontally positioned along the sides of the vessel’s hull and are often used to maintain stability during transportation or when cargo shifts within the vessel. Wing tanks can be subdivided into smaller compartments, allowing for better control over ballasting operations and reducing the potential risks associated with water ingress.

In addition to double-bottom tanks and wing tanks, many vessels in the Philippines also feature forepeak tanks. These forward-facing tanks are situated in the bow section of a ship and provide additional buoyancy where it is needed most. By utilizing forepeak tanks, ships can achieve optimal trim – maintaining their balance both vertically and horizontally – contributing to safer navigation through Philippine waters.

The variety of ballast tank configurations found in vessels across the Philippines highlights an industry commitment to safety and efficiency at sea. Understanding these different types of tanks allows us to appreciate not only their role in stabilizing ships but also their importance in ensuring smooth sailing for Philippine maritime trade.

Regulations and Standards for Vessel Ballast Tanks

Regulations and standards for vessel ballast tanks in the Philippines play a crucial role in ensuring maritime safety and environmental protection. As ships navigate through various Philippine ports and waters, they often need to adjust their weight distribution to maintain stability. Ballast tanks, which are compartments within the ship’s hull, are used to store water or other materials for this purpose.

To prevent potential contamination of marine ecosystems, international regulations such as the International Convention for the Control and Management of Ships’ Ballast Water and Sediments (BWM Convention) have been put in place. This convention sets standards for ballast water management systems to minimize the risk of introducing harmful aquatic organisms or pathogens into new environments. Additionally, several certification bodies ensure that vessels comply with these regulations by inspecting ballast tanks for structural integrity and cleanliness.

Despite existing regulations, there is still ongoing discussion regarding the implementation, enforcement, and improvement of vessel ballast tank standards. Some argue that current guidelines focus primarily on controlling biological organisms’ spread but overlook other important factors, such as sediment discharge or chemical pollution prevention. Striking a balance between protecting marine ecosystems and facilitating global trade poses an ongoing challenge that calls for continuous dialogue among industry stakeholders and regulatory bodies alike.

By providing insightful analysis of current challenges facing vessel ballast tank regulation while offering fresh perspectives on potential improvements, this blog section aims to engage readers in understanding the complexities surrounding maritime safety practices.

Vessel Ballasting Procedures in the Philippines

Vessel ballasting procedures in the Philippines play a crucial role in ensuring the safety and stability of ships. As a country with archipelagic geography, the Philippines is heavily reliant on maritime transportation for both trade and travel. Proper ballasting procedures are necessary to prevent accidents like capsizing or grounding, especially during extreme weather conditions.

One unique aspect of vessel ballasting in the Philippines is the consideration given to environmental protection. The country has stringent regulations in place to minimize ecological damage caused by ballast water discharge. Filipino shipowners are required to install effective treatment systems that remove harmful organisms from the ballast water before it is discharged into Philippine waters, reducing the risk of introducing invasive species.

Furthermore, vessel operators must navigate through a network of ports and harbors scattered across numerous islands (Luzon, Visayas, and Mindanao), making efficient ballasting procedures crucial for minimizing downtime and optimizing cargo operations. This requires careful planning and coordination to ensure proper tank utilization and weight distribution throughout the different stages of a voyage.

Vessel ballasting procedures in the Philippines encompass both safety considerations and environmental protection measures. By abiding by strict regulations regarding ballast water treatment and efficiently managing tank utilization during voyages, shipowners contribute not only to their own success but also to preserving the fragile marine ecosystem surrounding this beautiful country’s shores.

Maintenance and Inspection of Ballast Tanks

Maintenance and inspection of ballast tanks are crucial aspects of vessel management in the Philippines. These tanks, commonly found in ships, contain water or other liquids to provide stability during sailing. However, due to their constant exposure to seawater and various cargoes, they are prone to corrosion and deterioration over time.

Regular maintenance is essential to prevent the accumulation of sediments and debris that can lead to tank fouling. Inspections should be carried out at regular intervals to identify potential issues such as leaks, cracks, or structural damage. Utilizing advanced technologies like remote sensors and underwater drones can greatly enhance the efficiency of inspections by providing real-time data on the condition of the tanks.

Furthermore, proper coating systems must be applied periodically to protect against corrosion. Investing in high-quality coatings not only extends the lifespan of ballast tanks but also reduces maintenance costs in the long run. Additionally, regular cleaning procedures should be followed with appropriate detergents designed specifically for removing marine growth and preventing foul odors.

Maintaining ballast tanks requires a comprehensive approach that involves not only routine physical inspections but also consistent monitoring using modern technologies. Implementing an effective maintenance plan would not only ensure a safe operating environment for crew members but also promote environmental sustainability by preventing pollution caused by leaks or spills from deteriorating tank conditions.

Challenges and Solutions in Managing Vessel Ballast Tanks in the Philippines

Challenges and Solutions in Managing Vessel Ballast Tanks in the Philippines

Vessel ballast tanks play a crucial role in ensuring the stability and maneuverability of ships, but they also pose significant challenges, especially in countries like the Philippines. One of the primary difficulties is maintaining proper ballast tank maintenance and cleanliness. With the country’s tropical climate and high humidity levels, these tanks are prone to corrosion and fouling, which can compromise their structural integrity over time.

To address this challenge, proactive measures are essential. Regular inspections to identify early signs of corrosion or fouling can help prevent more significant issues down the line. Applying effective anti-corrosion coatings specifically designed for maritime environments can also provide long-term protection against rusting. Additionally, implementing proper cleaning protocols using environmentally friendly agents can help minimize fouling buildup without harming marine ecosystems.

Another key challenge faced in managing vessel ballast tanks is ensuring compliance with international regulations. The Philippines has been taking significant steps towards aligning its maritime industry with global standards, including those set by organizations like the International Maritime Organization (IMO). Compliance requires careful documentation of ballasting operations, adherence to disposal regulations for treated ballast water onshore facilities, and incorporating risk assessment procedures into vessel management systems.

These ongoing efforts towards tackling challenges associated with managing vessel ballast tanks reflect an industry-wide commitment to sustainable practices and safe maritime operations in the Philippines.

Need To Repair Your Vessel Ballast Tanks? ADMSI provides cost-effective and quality ship repair

When it comes to repairing vessel ballast tanks, Amaya Dockyard & Marine Services Inc. (ADMSI) is the go-to company for cost-effective and quality service in Cavite, Philippines. With their extensive experience in ship repair and maintenance, they have built a reputation for delivering exceptional results. Whether you are dealing with corrosion issues, leaks, or other structural problems in your ballast tanks, ADMSI has the expertise and state-of-the-art equipment to get the job done efficiently.

- Email us: info@amayadockyard.com

- Call our 24-hour hotline: +63 917 633 0479

- Viber: +63 917 633 0479

- WhatsApp: +63 917 633 0479

- Facebook Messenger: Click here

- Click here to inquire

One of the key advantages of choosing ADMSI for your vessel ballast tank repair needs is their commitment to providing cost-effective solutions. They understand that downtime can be costly for ship owners and operators, which is why they strive to streamline the repair process without sacrificing quality. By employing highly skilled technicians who are trained in the latest industry techniques, ADMSI ensures that your ballast tanks will be repaired promptly and effectively.

In addition to their focus on cost-effectiveness, ADMSI places a strong emphasis on delivering top-quality ship repairs. They pride themselves on using only high-grade materials and modern technologies to ensure long-lasting repairs that meet or exceed industry standards. Their knowledgeable team carefully assesses each ballast tank’s unique condition before developing a customized repair plan tailored to its specific needs. Whether it’s replacing corroded sections or reinforcing weak areas, ADMSI takes every necessary step to restore your vessel’s ballast tanks back to optimal condition.

Environmental Concerns and Best Practices for Ballasting

Ballasting is a crucial process in the shipping industry in the Philippines, but it also poses significant environmental concerns. One of the major issues is the introduction of invasive species through ballast water discharge. When ships take on ballast water from one location and then release it into another port, they unintentionally transfer harmful organisms that can disrupt local ecosystems. To address this concern, strict regulations have been put in place to ensure that ballast water is appropriately treated before being discharged. It is essential for ship owners and operators to adopt best practices for ballasting, such as using treatment systems that effectively remove or kill these organisms.

Another environmental concern associated with ballasting is the potential for oil spills and pollution in the Philippine Sea. Ballast tanks often contain residues of fuel oils and other hazardous substances that can leak during the process. To mitigate this risk, regular inspections and maintenance are critical to ensure the integrity of tank coatings and pipelines. Proper training should be provided to crew members involved in ballasting operations, emphasizing spill prevention techniques and prompt response procedures in case of an accident.

In addition to addressing these specific concerns, adopting environmentally friendly practices throughout the shipping industry can significantly contribute to reducing overall environmental impact. For instance, optimizing vessel design by reducing hull resistance through advanced hydrodynamics not only improves fuel efficiency but also decreases air emissions and subsequent greenhouse gas effects. Implementing energy-saving technologies like LED lighting or scrubbers can further reduce power consumption onboard while minimizing air pollution.

Final Words: Ensuring Safe and Efficient Vessel Operations with Vessel Ballast Tanks

In conclusion, Amaya Dockyard & Marine Services Inc. plays a crucial role in ensuring safe and efficient vessel operations with its expertise in maintaining and servicing vessel ballast tanks in Cavite, Philippines. With our state-of-the-art facilities and highly skilled technicians, we are able to provide comprehensive solutions that meet industry standards and regulations.

One key takeaway from this discussion is the importance of regular inspections and maintenance of ballast tanks. Neglecting these essential tasks can have severe consequences, ranging from corrosion and structural damage to environmental pollution. By partnering with ADMSI, Filipino shipowners not only guarantee compliance with regulatory requirements but also ensure the longevity and safety of their vessels.

Moreover, given the expanding maritime industry in the Philippines, it is crucial for Filipino boat owners to prioritize efficient vessel operations. The proper functioning of ballast tanks is integral to achieving this objective, as they directly impact a ship’s stability, maneuverability, and fuel efficiency. Through expert services provided by Amaya Dockyard & Marine Services Inc., Filipino shipowners can optimize their vessels’ performance while reducing operating costs and minimizing environmental impact.

Prioritizing vessel ballast tank maintenance with trusted partners like Amaya Dockyard & Marine Services Inc. is essential for ensuring safe sailing conditions, protecting marine ecosystems, complying with regulations, and maximizing efficiency in today’s Philippine maritime landscape.

Enhance your understanding of vessel ballast tanks with our all-inclusive guide. From design to maintenance, ADMSI got you covered for smooth sailing.