The vast ocean hides a world of mysteries and wonders, including colossal vessels that navigate its depths. But what happens when these mighty ships require repairs in the very environment they call home? Enter underwater machinery ship repair, an intricate process that combines cutting-edge technology, skilled divers, and ingenious engineering. In this article, we will take a deep dive into the fascinating world of underwater machinery ship repair in the Philippines, exploring the challenges faced by engineers and divers alike as they work beneath the surface to keep these floating giants afloat and functioning at their best.

Click here to view our ship repair services.

Understanding The Importance Of Underwater Machinery Ship Repair in the Philippines

Underwater machinery ship repair plays a crucial role in ensuring the durability and performance of marine vessels in the Philippines. It involves the maintenance and repair of various equipment and systems submerged beneath the waterline, such as propellers, thrusters, shafts, and rudders. While regular inspections and surface-level repairs are necessary for any vessel, addressing issues that arise below the waterline is equally important.

One key aspect that contributes to the significance of underwater machinery ship repair in Metro Manila and Cavite is the prevention of costly downtime. Maritime operations heavily rely on efficient ship functioning to maintain schedules and meet customer demands. Any unexpected failure or malfunction of underwater machinery can lead to significant delays or even cancellations of trips, resulting in financial losses for shipping companies. Timely repair and maintenance services minimize these risks by identifying potential issues before they escalate into major problems.

Moreover, proper underwater machinery ship repair in the Philippines also ensures safety at sea. Faulty or ineffective equipment can compromise navigation capabilities, making vessels vulnerable to accidents or collisions with other ships or natural obstacles like reefs. By promptly addressing any mechanical failures underwater, ship repair specialists contribute to reducing maritime accidents and enhancing overall sea navigation safety standards.

Understanding the importance of underwater machinery ship repair in the Philippines goes beyond maintaining vessel aesthetics; it directly impacts operational efficiency, cost-effectiveness, and safety at sea. Investing in experts who possess specialized knowledge regarding these intricate repairs leads to sustainable business practices while prioritizing crew members’ well-being and cargo delivery efficiency.

Types Of Underwater Machinery In Ships In The Philippines

When it comes to ship repair and maintenance in the Philippines, underwater machinery plays a crucial role in ensuring the smooth operation of ships. From complex hydraulic systems to cutting-edge propulsion technology, there are various types of underwater machinery that help keep ships afloat and functioning optimally.

One important type of underwater machinery is the bow thruster. This device, often found in larger vessels, enables a ship to maneuver more easily by generating lateral propulsion. By directing water flow with specialized propellers located at the front of the ship, bow thrusters enhance docking operations and improve overall maneuverability.

Another essential piece of underwater machinery is the marine growth cleaning system. Over time, marine organisms such as barnacles and algae can accumulate on a ship’s hull, reducing its efficiency and increasing fuel consumption. To combat this issue, specialized cleaning systems use high-pressure water jets or brushes to remove built-up biofouling from the hull surface while minimizing damage to the underlying protective coatings.

These types of underwater machinery are just some examples of how technology continues to advance in maintaining efficient and sustainable maritime transportation. Whether it be supporting navigation or fighting against biofouling, these innovative solutions ensure ships remain operational while minimizing environmental impact – an imperative for today’s shipping industry.

Challenges Faced In Underwater Machinery Ship Repair In The Philippines

Underwater machinery ship repair Cavite, Cebu, Davao, and Clark Zambales is an intricate process that poses numerous challenges to engineers and technicians. One of the primary hurdles in this field is the limited visibility underwater, which can make it difficult to identify and assess potential issues. The murky water, coupled with poor lighting conditions, significantly hampers the ability to locate specific machinery components that require repair or replacement. Technicians often have to rely on their experience, knowledge, and intuition to navigate through these challenging conditions.

Another significant challenge in underwater machinery ship repair in the Philippines is corrosion. Constant exposure to saltwater causes accelerated deterioration of metal surfaces, leading to rusting and degradation of critical machine parts. This corrosion problem not only affects the performance of the machinery but also makes it more susceptible to complete failure. Repairing corroded components requires specialized techniques such as sandblasting and coating systems designed for underwater applications.

Furthermore, working in confined spaces while conducting repairs adds another layer of complexity to underwater machinery ship repair in the Philippines. These tight spaces limit mobility and make it challenging for engineers and technicians to access faulty equipment easily. Moreover, ensuring proper ventilation becomes crucial due to reduced airflow in confined areas, posing additional occupational hazards related to air quality management.

Underwater machinery ship repair in Metro Manila presents a unique set of challenges that demand innovative solutions and meticulous planning. The limitations imposed by restricted visibility, corrosion issues resulting from constant exposure to saltwater, and working within confined spaces all contribute towards making this field a demanding one for professionals involved in repairing marine equipment at sea depths.

Process Of Underwater Machinery Ship Repair In The Philippines

Underwater machinery ship repair in Tanza Cavite is a complex and fascinating process that requires specialized skills, equipment, and expertise. Unlike traditional ship repairs performed in dry docks, underwater repairs present unique challenges due to the underwater environment. Ship repair technicians must undergo rigorous training to handle these complex tasks with precision.

One of the critical steps in underwater machinery ship repair in Luzon, Visayas, and Mindanao is inspection. Before diving into repairing the machinery, thorough inspections are conducted to assess the extent of damage and identify potential issues. This involves using remotely operated vehicles (ROVs) equipped with high-definition cameras and sensors to gather data on the condition of the machinery. These inspections ensure that technicians have a clear understanding of what needs to be repaired or replaced.

Once the inspection is complete, preparations are made for repairing or replacing damaged parts. Underwater welding techniques are commonly used to carry out these repairs effectively. Welding in an underwater environment requires highly skilled welders who can work under intense pressure while maintaining utmost precision. Special precautions, such as pre-weld cleaning and protective coatings, are taken to prevent corrosion caused by saltwater exposure.

Underwater machinery ship repair in the Philippines is a challenging task that demands expertise beyond traditional ship repairs performed in dry docks. From comprehensive inspections using ROVs to intricate welding techniques performed under water pressure, every step of this process requires careful planning and execution by highly trained professionals.

Tools And Equipment Used For Underwater Repairs In The Philippines

When it comes to underwater repairs in Cebu, Davao, Manila, Batangas, Cavite, and Zambales, having the right tools and equipment is crucial. One of the most common tools used for repairing underwater machinery is a submersible welding machine. This powerful tool allows welders to work in submerged conditions, providing a reliable and efficient way to repair damaged parts of ships and other underwater structures.

Another essential piece of equipment used for underwater repairs is a remotely operated vehicle (ROV). These small unmanned submarines are equipped with cameras and mechanical arms that can perform intricate tasks in deep-sea environments. ROVs are especially useful for inspecting and repairing hard-to-reach areas, making them invaluable for ship repair projects.

Additionally, divers often rely on specialized cutting tools like hydraulic shears and diamond wire saws when working on underwater repairs. These tools make it possible to cut through metal, concrete, or other materials quickly and accurately while ensuring minimal disruption to the surrounding environment.

The combination of submersible welding machines, ROVs, and cutting tools empowers engineers and technicians to tackle even the most challenging underwater repair projects efficiently. By embracing these advanced technologies, professionals can not only enhance their safety but also improve productivity during ship repairs while minimizing downtime at sea.

Step-by-step Process Of Underwater Machinery Ship Repair In The Philippines

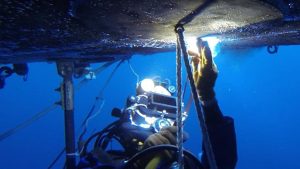

Underwater machinery ship repair in the Philippines is a complex and highly specialized process that requires skilled technicians, advanced equipment, and careful planning. The first step in this intricate procedure involves the inspection of the underwater machinery to assess the extent of damage or malfunction. This is usually done by divers equipped with underwater cameras and other tools.

Once ADMSI engineers complete the inspection, the next step is to create a detailed repair plan. This includes identifying the specific repairs required for each piece of machinery and estimating the time, resources, and manpower needed for the job. It’s crucial to carefully evaluate all aspects of the repair plan to ensure safety, efficiency, and effectiveness.

Afterward comes one of the most challenging parts: preparing for the actual repair work underwater. Technicians must don diving suits and enter deep waters equipped with specialized tools necessary for repairing complex machinery systems. The repairs may involve replacing damaged components or performing intricate maintenance tasks that require precision and expertise.

Throughout every stage of underwater machinery ship repair in the Philippines, strict safety protocols are followed to guarantee that both human personnel and marine life are not put at risk. Adherence to these guidelines ensures a successful outcome and guarantees that all repairs are carried out without causing any further harm or compromising vessel integrity.

Performing underwater machinery ship repair in the Philippines demands meticulous planning, expert evaluation skills for damage assessment, as well as extensive training for carrying out technical procedures effectively under challenging conditions.

Safety Precautions During Underwater Machinery Ship Repair In The Philippines

Safety precautions are of utmost importance during underwater machinery ship repair in the Philippines to ensure the well-being of the personnel involved as well as the successful completion of the project. One key aspect is ensuring that all workers are equipped with proper personal protective equipment (PPE), such as diving suits, helmets, gloves, and safety glasses. These PPEs not only protect against potential physical injuries but also shield from harm caused by hazardous chemicals and potential underwater contaminants.

Another crucial safety consideration is providing comprehensive training to all workers before they embark on any repairs in a submerged environment. They should undergo rigorous instruction on proper handling of tools and equipment, emergency procedures, dive planning, and, most importantly, practicing controlled breathing techniques to manage rapid changes in pressure when returning to the surface. In addition to this initial training, regular refresher courses should be conducted to ensure continued competence in safety protocols.

As part of risk assessment measures, it is vital to conduct thorough inspections prior to commencing any repairs. This includes evaluating water conditions such as visibility, current strength, temperature fluctuations, and any possible presence of marine life that can pose a danger during work activities. Machinery should also undergo meticulous examination for damaged or lost components before divers are allowed near them. By taking these precautions seriously and designing a robust safety blueprint for underwater machinery ship repair projects in Cavite, Batangas, Zamboanga, Cebu, Palawan, and Mindoro, we can not only minimize risks but also foster an environment where workers’ health and well-being take precedence over everything else.

Looking For An Underwater Machinery Ship Repair Company In The Philippines?

When it comes to finding an underwater machinery ship repair company in the Philippines, look no further than Amaya Dockyard & Marine Services Inc. With a proven track record for being the most cost-effective and reliable company in the industry, we offer top-notch services that are tailored to meet your specific needs.

- Email us: info@amayadockyard.com

- Call our 24-hour hotline: +63 917 633 0479

- Viber: +63 917 633 0479

- WhatsApp: +63 917 633 0479

- Facebook Messenger: Click here

- Click here to inquire

What sets Amaya Dockyard & Marine Services Inc. apart from other companies is their team of highly skilled professionals who have years of experience in underwater machinery ship repair in Tanza, Cavite. Our expertise, combined with state-of-the-art equipment, ensures that every project is completed with the utmost precision and efficiency.

Moreover, Amaya Dockyard & Marine Services Inc. understands the importance of timely repairs to keep your operations running smoothly. We pride ourselves on delivering prompt service without compromising on quality, making them a trusted partner for both local Filipino maritime companies and international clients.

Whether you need routine maintenance or complex repairs, Amaya Dockyard & Marine Services Inc. has got you covered. Our commitment to customer satisfaction and dedication to excellence make us the go-to choice for any underwater machinery ship repair needs in the Philippines. Trust us to keep your vessels in optimal condition, allowing you to focus on what matters most: navigating to success on the high seas!

Final Thoughts: Importance Of Maintaining And Repairing Underwater Machinery

In conclusion, it is evident that maintaining and repairing underwater machinery in Cavite, Metro Manila, Cebu, and Zambales plays a crucial role in ensuring the smooth operation and longevity of ships. With advancements in technology, the need for regular upkeep has become even more evident. Neglecting maintenance can lead to unexpected breakdowns, costly repairs, and even accidents that can threaten lives.

One key aspect of maintaining underwater machinery is preserving fuel efficiency. A well-maintained propulsion system reduces drag and optimizes performance, resulting in lower fuel consumption. This not only saves costs but also has a positive impact on the environment by reducing carbon emissions.

Furthermore, proper maintenance allows for the early detection of minor defects before they escalate into major issues. Regular inspections and timely repairs help prevent catastrophic failures that could result in downtime or even the scrapping of an entire ship. By investing in scheduled maintenance programs, ship owners can ensure uninterrupted operations while extending the lifespan of their vessels.

Overall, it is clear that neglecting to maintain and repair underwater machinery can have severe consequences, both economically and from a safety standpoint. Ship owners must recognize the value of proactive upkeep to avoid costly repairs and enhance performance and efficiency while promoting sustainable practices within the maritime industry.

Embark on a journey to uncover the incredible techniques and skills behind underwater machinery ship repair in the Philippines. Dive into this captivating industry today.