The Philippines, known for its stunning beaches and vibrant marine life, is also a bustling hub for ship repair and maintenance. Among the various methods employed in the industry, drydocking and afloat repair works stand out as crucial processes that ensure the longevity and efficiency of vessels. In this article, we will delve into these fascinating practices, shedding light on their significance in keeping ships seaworthy while exploring their intricacies within the context of the Philippines’ maritime industry. Whether you are a maritime enthusiast or simply curious about how ships are maintained, join us as we unravel the world of drydocking and afloat repair works in the Philippines.

Click here to view our ship repair services.

Understanding the Basics of Drydocking and Afloat Repair Works in the Philippines

Afloat repair works in the Philippines have become increasingly important as the country’s maritime industry continues to grow. Afloat repair refers to any repairs and maintenance work carried out on a vessel while it is still in water without the need for drydocking. This method is not only cost-effective but also ensures minimal downtime for ships, making it an attractive option for shipowners and operators.

One of the key advantages of afloat repair works is that they can be conducted at any time, regardless of weather conditions. Unlike drydocking, which requires vessels to be taken out of the water and placed in a dock or slipway, afloat repairs can be carried out while the ship is still afloat. This means that even if there are urgent repairs or maintenance needed, they can be done quickly without having to wait for suitable weather conditions or the availability of dry docks.

Furthermore, afloat repair works in Manila, Cavite, Subic Bay, Batangas, Navotas, and Cebu offer flexibility in terms of location. With drydocking, ships need to travel to specific locations that have suitable facilities for docking. In contrast, afloat repairs can take place wherever there is access to water and appropriate equipment. This allows ships to undergo necessary maintenance and repairs even in remote areas where dry docks may not be available.

Understanding the basics of drydocking and afloat repair works in the Philippines showcases innovative approaches toward ship maintenance and sets the stage for continued growth within the maritime industry.

Reasons for Drydocking: Maintenance, repairs, and inspections in the Philippines

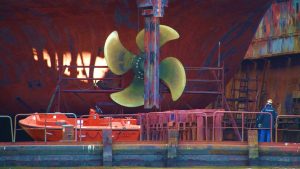

One of the primary reasons for drydocking a ship in the Philippines is to conduct maintenance and repairs. Drydocking provides a controlled environment where necessary work can be efficiently carried out without being hindered by adverse weather conditions or limited access to specialized equipment. It allows for thorough inspections of the vessel’s hull, propellers, and other essential components, enabling maritime professionals to address any signs of wear and tear promptly. Moreover, drydocking also offers an opportunity for proactive maintenance, including applying anti-fouling paint to prevent the build-up of marine growth and ensure optimal performance.

In addition to maintenance and repairs, drydocking in the Philippines allows for comprehensive inspections that are crucial from both safety and regulatory perspectives. The process involves conducting detailed surveys on various aspects of the ship’s structure, machinery systems, electrical installations, fire-fighting equipment, navigation aids, and more. These inspections help ensure compliance with international standards set by organizations such as the International Maritime Organization (IMO) and flag state authorities. By adhering to these rigorous inspection procedures during drydocking in the Philippines, ship owners demonstrate their commitment to maintaining high safety standards while enhancing operational efficiency.

Drydocking not only facilitates afloat repair work but also offers numerous advantages that extend beyond mere maintenance. With its strategic location in Southeast Asia’s vibrant shipping hub, the Philippines boasts numerous skilled workers trained in various marine-related professions who contribute significantly to efficient operations in drydock facilities across the country.

Process of Drydocking: Preparation, Haul-out, and Work Scope in the Philippines

Once the decision has been made to drydock a vessel in the Philippines, thorough preparations are necessary to ensure a smooth process. These preparations involve gathering all relevant documentation, such as docking plans and survey reports, as well as coordinating with various parties involved, including shipyard personnel and service providers. This crucial step ensures that everyone is well-informed about the scope of work to be carried out during drydocking.

The day of haul-out is always an exciting one for both shipowners and shipyard workers alike. As the vessel approaches the designated slipway or floating drydock, skilled personnel carefully maneuver it into position using tugboats or other auxiliary crafts. The precision required during this operation is astounding, as even a minor error can lead to costly damage.

With the vessel securely docked in place, it’s time for the real work to begin. Afloat repair works in Luzon, Visayas, and Mindanao may include tasks such as hull cleaning and painting, propeller polishing, sea chest cleaning and inspection, and various machinery overhauls. During this phase, meticulous attention to detail is required from all involved parties to ensure that each task is completed efficiently and effectively.

Here are the Processes of Drydocking in the Philippines:

Pre-drydock Preparation: First Process of Drydocking in the Philippines

Pre-drydock preparation is a critical step in the drydocking process in the Philippines. It involves meticulous planning and coordination between various stakeholders to ensure a smooth and efficient operation. One key aspect of pre-drydock preparation is the inspection and assessment of the vessel’s condition. This helps identify any necessary repairs or maintenance works that should be carried out during the drydocking period.

Another vital task during this stage is establishing an effective working relationship with suppliers and contractors who will be involved in the drydocking project. This ensures that all necessary equipment, materials, and manpower are organized well in advance, minimizing delays and ensuring that everything runs according to schedule once the ship arrives at the dockyard. Effective communication plays a crucial role here, as it allows for proactive planning and coordination between all parties involved.

Pre-drydock preparation sets the foundation for a successful drydocking operation. By thoroughly assessing the vessel’s condition, establishing strong partnerships with suppliers and contractors, and implementing effective communication channels, Filipino ship owners can ensure cost-effective repairs or maintenance work while minimizing downtime. The Philippines’ reputation as a reliable destination for drydocking services greatly depends on these preparatory efforts—and getting them right makes all the difference when it comes to meeting deadlines while delivering quality results for shipowners around the world.

Docking the Vessel: Second Process of Drydocking in the Philippines

Docking the vessel is a critical stage in the drydocking process that ensures the ship is securely positioned for repair and maintenance. In the Philippines, this second stage requires meticulous planning and expert knowledge to ensure a smooth operation. The docking procedure involves carefully guiding the vessel into a dock or slipway, followed by securing it in place using advanced mooring techniques.

One of the key challenges faced during this process is ensuring the proper alignment and positioning of the vessel. Every ship has unique characteristics that need to be taken into account, such as size, weight distribution, draft depth, and water depth at the dock. Shipyards in the Philippines use innovative methods like utilizing tugs and maneuvering ropes to position vessels within docking areas safely. These techniques require skilled personnel who are well-versed in ship-handling principles and have extensive experience in navigating ships of various sizes and types.

Moreover, docking provides an opportunity for a thorough inspection of the hull and other underwater components, which are not easily accessible when the ship is floating. This inspection allows for a better assessment of any damage or corrosion present in these areas and enables repairs to be performed efficiently. The drydock provides a controlled environment where skilled technicians can work on different aspects of maintenance, such as painting, welding, propeller repairs, or even major overhauls.

Docking plays a crucial role in drydocking operations in the Philippines. It requires careful planning and execution to ensure the optimal positioning of vessels for repair works while offering access to submerged parts that may require attention.

Inspection and Repairs: Third Process of Drydocking in the Philippines

Inspection and repairs constitute the third critical process of drydocking in the Philippines. This phase involves a comprehensive assessment of the vessel’s hull structure, machinery, and equipment to identify any issues or damages that need to be addressed. Skilled technicians conduct thorough inspections using advanced technology such as ultrasonic thickness gauges and diving surveys to ensure all areas are assessed accurately.

Once any deficiencies or defects are detected, repair works begin promptly. The shipyard teams collaborate closely with the vessel owners and classification societies to develop repair plans that prioritize safety, efficiency, and compliance with industry standards. From welding repairs to structural modifications and equipment overhauls, experienced technicians handle a wide range of tasks during this stage.

The inspection and repair process not only ensures the seaworthiness of vessels but also extends their operational lifespan. By identifying potential problems early on and implementing necessary repairs, shipowners can prevent more significant damage in the future. Effective inspections combined with quality repair work contribute to maintaining high safety standards for vessels operating in Philippine waters. Industrial experts continue innovating inspection methods for drydocking processes through digitalization and advanced technologies like remote underwater vehicle inspections (ROV) – further improving efficiencies in this crucial maintenance phase.

Undocking the Vessel: Fourth Process of Drydocking in the Philippines

Undocking the vessel is a critical stage in the drydocking process, marking the beginning of the final phase before the ship can return to its intended operations. Once all necessary repairs and maintenance have been completed during the stay in drydock, it is time for the vessel to leave its temporary home and head back to sea.

Undocking requires meticulous planning and coordination between various parties involved, including dock workers, tugboat operators, and onboard crew members. The vessel needs to be carefully maneuvered out of its berth using powerful tugboats while also considering factors such as tidal conditions and weather patterns. This delicate dance of precision ensures that undocking is carried out smoothly without any mishaps or damage.

The undocking process not only signifies the end of an extensive repair period but also brings with it a sense of accomplishment for everyone involved. It symbolizes a successful collaboration between shipyard professionals who diligently worked to restore the vessel’s seaworthiness. As the ship gracefully leaves behind its temporary sanctuary, ready to embark on its forthcoming voyages with renewed strength, one can’t help but marvel at the seamless transition from drydock back into action on open waters.

The drydocking process in the Philippines involves extensive preparation work prior to haul-out. Once in position on the slipway or floating drydock, a wide range of afloat repair works take place, which require careful planning and execution.

Afloat Repair Works: Importance and Common Types in the Philippines

Afloat repair works play a crucial role in the maritime industry in the Philippines. The archipelagic nature of the country, with its numerous islands and bustling ports, necessitates efficient maintenance and repair services for vessels that may not be able to dock at shipyards. Afloat repair works in Cavite, Cebu, Navotas, Zambales, and Davao are essential for keeping ships operational, ensuring their safety and compliance with regulations, and minimizing downtime.

There are several common types of afloat repair works carried out in the Philippines. One important type is hull cleaning and painting. Regular maintenance of a vessel’s hull is vital to prevent corrosion, fouling, and other damage caused by prolonged exposure to seawater. Additionally, mechanical repairs such as welding or replacement of damaged components are frequently conducted afloat as well. These repairs can range from minor fixes to major overhauls, all aimed at keeping the vessel fully functional while at sea.

Afloat repair works serve as a vital lifeline for ships operating in Philippine waters. They keep vessels in optimal condition and ensure smooth operations without having to wait for berths at overcrowded shipyards. With the increasing demand for maritime transport in the country, it is imperative that these services continue to evolve and adapt to provide efficient solutions that meet the growing needs of this rapidly expanding industry.

Process of Afloat Repair Works in the Philippines

Here is the process of afloat repair works in the Philippines:

Step 1: Assessment and Identifying the Scope of Repair Work

Assessment and identifying the scope of repair work is a critical first step in any afloat repair project in the Philippines. This stage involves evaluating the current condition of the vessel or structure, determining the extent of damage or wear and tear, and formulating an action plan for necessary repairs. By conducting a thorough assessment, shipyard crews can ensure that all areas requiring attention are properly identified and addressed, minimizing unexpected surprises during the repair process.

One key aspect of this initial assessment is considering various external factors that may have contributed to the vessel’s deterioration. In an archipelagic country like the Philippines, where ships regularly navigate through tropical waters with high salt content, corrosion poses a significant challenge. Thus, assessing not only visible damage but also potential underlying issues caused by corrosion becomes crucial for effective repair planning.

Furthermore, modern technologies such as non-destructive testing (NDT) methods have become invaluable tools in accurately assessing and identifying hidden damages. Techniques such as ultrasonic testing (UT) can help detect internal flaws or defects that might not be visible to the naked eye. Incorporating these advancements into the assessment process ensures a more precise understanding of both obvious and concealed repairs needed for successful afloat repairs in Philippine waters.

Thorough assessment and identification of repair requirements lay down strong foundations for successful afloat repair works in the Philippines. These preliminary steps allow shipyard crews to devise strategic plans tailored to specific vessels’ needs while considering environmental factors like corrosive tropical conditions.

Step 2: Planning:

Developing a detailed repair plan is the second step in afloat repair works in the Philippines.

Developing a detailed repair plan is crucial for successful afloat repair works in the Philippines. It involves careful assessment of the vessel’s condition, identification of specific repair needs, and formulation of an effective step-by-step strategy. One important aspect to consider during this planning phase is the availability of resources and manpower necessary to carry out the repairs. By carefully planning out the repair process, Filipino ship owners can minimize downtime and ensure that work progresses smoothly.

A crucial part of developing a repair plan is conducting a thorough inspection. This involves assessing all damaged or defective areas on the ship, including machinery, electrical systems, hull structure, and coatings. This initial assessment will help determine not only what needs to be repaired but also what materials and skills will be required for each task. A comprehensive understanding of these requirements enables planners to allocate resources efficiently, avoiding costly delays or inadequate repairs.

Step 3: Mobilization:

Gathering necessary resources and equipment is the third step in afloat repair works in the Philippines.

Mobilization is a crucial step in any afloat repair work undertaken in the Philippines. This involves gathering all the necessary resources and equipment needed for the job at hand. It may seem like a simple task, but it requires careful planning and coordination to ensure that everything is readily available when needed.

One of the challenges faced during mobilization is sourcing the required materials, especially for remote locations. With scattered islands and limited access to transportation, getting supplies to these areas can be difficult. This necessitates effective logistics management to ensure the timely delivery of essential items like spare parts, tools, and even skilled personnel.

Another aspect of mobilization that should not be overlooked is safety equipment. The maritime environment presents unique hazards that must be mitigated to protect workers’ well-being. Life jackets, helmets, gloves, goggles – these are just some of the items that need to be procured and distributed among the repair crew.

Overall, mobilization plays an integral role in afloat repair works in the Philippines. It sets the foundation for the successful completion of repairs by ensuring that all resources and equipment are readily available on-site.

Step 4: Execution

Carrying out the repair work at sea is the fourth step in afloat repair works in the Philippines.

Execution is the crucial stage in any afloat repair work, especially when it takes place at sea. It requires meticulous planning, precise coordination, and swift action to ensure smooth operations. One of the key challenges faced during repairs at sea is the constant movement of the vessel on waves. This adds an element of complexity as workers have to adapt and adjust their movements accordingly.

The execution phase involves a range of activities such as welding, pipe fitting, hull cleaning, painting, and electrical repairs, among others. Each task requires specialized skills and expertise to be performed effectively. What’s interesting about executing repairs at sea is that it demands a high level of adaptability from workers who have to contend with limited space and resources. They must come up with innovative solutions on the spot while being mindful of safety regulations and environmental concerns.

Moreover, execution at sea offers unique insights into problem-solving techniques that cannot be replicated in traditional repair settings. As workers carry out repairs amidst turbulent waters and unpredictable weather conditions, they develop a heightened sense of resilience and resourcefulness. This experience fosters valuable qualities such as quick thinking under pressure and creative troubleshooting skills that can prove invaluable in future repair endeavors.

Execution in afloat repair works at sea is an intricate process that necessitates careful planning, skilled laborers, flexible working methods, and quick thinking on the go.

Step 5: Quality control

Ensuring the repairs meet standards is the fifth step in afloat repair works in the Philippines.

Quality control plays a crucial role in ensuring that the repairs conducted during afloat repair works in the Philippines meet the required standards. It is not enough to simply fix what is visibly broken; it is equally important to ensure that the repaired components can withstand various environmental and operational conditions. This involves rigorous testing, thorough inspections, and adherence to strict quality assurance protocols.

One aspect of quality control in afloat repair works is conducting comprehensive tests on repaired equipment or systems. For instance, if a damaged pump is replaced, it must undergo performance tests to ensure that it operates efficiently under different flow rates and pressures. Similarly, electrical systems should be thoroughly examined for compliance with electrical safety standards. By subjecting the repaired components to extensive testing, shipyards can confidently deliver vessels that are reliable and capable of meeting operational requirements.

In addition to testing, regular inspections play an integral role in maintaining quality control during afloat repair works. Inspections involve examining repaired areas for any signs of substandard workmanship or potential issues that may arise in the future. This process helps identify any areas requiring further attention or correction before they become major problems while at sea. A meticulous approach towards inspections ensures that all repairs have been executed correctly and meet industry standards so as not to compromise vessel integrity or performance.

Quality control measures are essential steps in completing successful afloat repair works in the Philippines.

Advantages of Drydocking vs. Afloat Repair Works

One advantage of drydocking over afloat repair works in the Philippines is the ability to inspect and assess the condition of the vessel thoroughly. When a ship is in drydock, it can be lifted out of the water, allowing for a comprehensive inspection of the hull and other underwater components. This allows for any necessary repairs or maintenance to be identified and addressed before they become major problems. In contrast, with afloat repair works, only certain areas can be accessed while the vessel is still in the water, limiting the scope of the inspection and potentially leaving hidden damage unnoticed.

Another advantage of drydocking is that it allows for more extensive repairs and modifications to be carried out. Since a docked ship is completely out of the water, there are no restrictions on accessing different parts of the vessel or working at various levels below the waterline. This makes it possible to undertake complex repairs or structural modifications that would otherwise be difficult or impossible to do while floating. In addition, drydocking provides ample space for equipment and materials needed for such tasks, ensuring efficiency and safety during repair work.

While afloat repair works may offer convenience in terms of not having to remove a vessel from service, drydocking provides several distinct advantages. From thorough inspections to extensive repairs and modifications, drydocking ensures that vessels are maintained at their best condition without compromise.

Advantages of Afloat Repair Works vs. Drydocking

There are several advantages to opting for afloat repair works over drydocking.

First, afloat repairs can be carried out without disrupting vessel operations or causing delays in the shipping schedule. While drydocking requires the vessel to be taken out of service and placed in a shipyard, afloat repair works can be conducted while the vessel remains functional, minimizing downtime and ensuring smooth operations.

Second, afloat repair works are often more cost-effective compared to drydocking. Drydocking involves significant expenses such as docking fees, transportation costs, and additional labor costs associated with moving the vessel in and out of the shipyard. Afloat repairs eliminate these additional expenses, making it an economically viable option for companies looking to save costs without compromising on quality.

Last, afloat repairs offer greater flexibility when it comes to selecting suitable repair locations. Instead of being limited to specific shipyards that have drydock facilities available at certain times or locations, vessels can undergo repairs at any accessible port. This flexibility allows for quicker response times and more efficient scheduling of repairs.

While both drydocking and afloat repair works have their own merits depending on the extent of damage or maintenance required for a vessel, choosing afloat repair works provides advantages such as minimal disruption in operations, cost savings, and increased flexibility in selecting suitable locations for repairs. Considering these benefits is crucial when deciding how best to optimize resources while ensuring timely maintenance and uninterrupted sailing schedules.

Factors to Consider when Choosing Between Drydocking and Afloat Repair Works

When a ship requires repair or maintenance work, Filipino shipowners and operators are faced with the decision of whether to opt for drydocking or afloat repair works. Both options have their advantages and disadvantages, and choosing the right one is crucial in ensuring a cost-effective and efficient solution.

One factor to consider is the nature and severity of the repairs needed. If extensive repairs are necessary, such as replacing hull plates or propeller shafts, drydocking may be the better choice as it provides easier access to the entire hull of the vessel. On the other hand, if minor repairs or routine maintenance tasks can be carried out without requiring complete isolation from water, afloat repair works may be more practical.

Another important consideration is timing and availability. Drydocking typically takes longer than afloat repair works due to the time required for preparations, lifting or hauling out of vessels, and re-floating after completion. This can result in significant downtime for ships that need quick repairs. In contrast, afloat repair works allow vessels to remain operational during maintenance or minor repairs, minimizing disruptions in their schedules.

Ultimately, selecting between drydocking and afloat repair works will depend on various factors specific to each individual vessel’s condition and operational needs. Shipowners should carefully evaluate these considerations before making a decision that best suits both their budgetary constraints and operational requirements ‒ ensuring an effective solution is achieved while maintaining minimal disruption to their business operations at sea.

Benefits of Drydocking and Afloat Repair Works in the Philippines

Drydocking and afloat repair works in the Philippines offer numerous benefits to shipowners and operators. One key advantage is the skilled workforce available in the country, which is known for its high-quality craftsmanship at competitive rates. Shipyards in the Philippines have experienced and well-trained professionals who are equipped to handle various repair and maintenance tasks, ensuring that vessels are restored to their optimal condition.

Additionally, drydocking and afloat repair works in the Philippines can be more cost-effective compared to other countries. The relatively low labor costs allow for significant savings without compromising on quality. Furthermore, with several major ports strategically located throughout the country, accessing shipyards for repairs or inspections becomes convenient for both domestic and international vessels passing through Philippine waters.

Another benefit of drydocking and afloat repair works in the Philippines is access to advanced facilities and technologies. Many shipyard facilities are equipped with state-of-the-art equipment, including dry docks with large lifting capacities, advanced fabrication workshops, modern machine shops, painting booths, and NDT testing capabilities. These cutting-edge facilities ensure efficient project execution and enable shipyards to cater to various types of vessels regardless of size or complexity.

From skilled workforce availability to cost-effectiveness and access to advanced facilities, drydocking and afloat repair works in the Philippines provide significant advantages for shipowners seeking reliable maintenance solutions. Coupled with favorable geographic locations and competitive pricing structures, it’s no wonder many entities choose the Philippines as their go-to destination for vessel repairs.

Challenges and Considerations in Drydocking Operations in the Philippines

One of the major challenges in drydocking operations in the Philippines is the unpredictability of weather conditions. The country’s geographical location makes it prone to typhoons and heavy rainfall, which can disrupt schedules and prolong drydocking processes. To mitigate this challenge, shipyard operators in the Philippines need to incorporate robust weather monitoring systems and have contingency plans in place to ensure the safety of both workers and vessels.

Another consideration in drydocking operations is the availability of skilled labor. While there are many highly skilled workers in the Philippines, meeting the demand for expertise specific to ship repair can sometimes be challenging. Shipyard operators need to invest in training programs and partnerships with educational institutions to develop a skilled workforce capable of handling complex drydocking operations efficiently. Additionally, fostering a culture of continuous learning and innovation within shipyards can help overcome this hurdle by encouraging upskilling among employees.

While there are challenges and considerations unique to drydocking operations in the Philippines, industry players can navigate these hurdles through careful planning, investment in resources, and collaboration with other stakeholders. By addressing these challenges head-on, shipyard operators can unlock opportunities for growth and contribute to enhancing the country’s maritime sector as a hub for efficient drydock repairs.

Challenges and Considerations in Afloat Repair Works in the Philippines

One of the biggest challenges in afloat repair works in the Philippines is the unpredictable weather conditions. The country experiences frequent typhoons and heavy rain that can delay or even halt repair works. Shipowners and repair facilities need to carefully plan and schedule repairs during months when the weather is relatively stable to minimize disruptions and costly delays.

Another important consideration in afloat repair works is ensuring compliance with environmental regulations. The Philippines has strict environmental laws, particularly when it comes to waste management and pollution prevention. Repair facilities must have proper facilities and procedures in place to handle hazardous materials appropriately, treat wastewater before discharge, and properly dispose of solid waste generated during repairs.

Additionally, logistical challenges can arise due to the scattered nature of shipyards in the Philippines. There are multiple shipyard locations across the archipelago, each with its own specific limitations in terms of capacity, equipment availability, skilled labor force, and accessibility. Shipowners need to carefully consider which yard best suits their needs based on these factors to ensure efficient and effective afloat repairs within acceptable timeframes.

While afloat repair works offer advantages such as reduced downtime compared to drydocking, there are various challenges that need to be taken into account for successful operations in the Philippines, including unpredictable weather conditions, compliance with environmental regulations, and logistical considerations associated with shipyard selection.

Are You Looking for the Best Drydocking and Afloat Repair Works Company in the Philippines?

When it comes to drydocking and afloat repair works in the Philippines, Amaya Dockyard & Marine Services Inc. (ADMSI) stands out as one of the best companies in the industry. With our commitment to quality and professionalism, we have established ourselves as a trusted partner for all types of vessel repairs. Whether you need routine maintenance or extensive repairs, ADMSI has the expertise and resources to meet your needs.

- Email us: info@amayadockyard.com

- Call our 24-hour hotline: +63 917 633 0479

- Viber: +63 917 633 0479

- WhatsApp: +63 917 633 0479

- Facebook Messenger: Click here

- Click here to inquire

What sets ADMSI apart from other companies is our dedication to customer satisfaction. We understand that time is of the essence in shipping operations, and any delay can result in significant financial losses. That’s why we strive to complete projects on time and within budget without compromising on quality. Our team of skilled Filipino technicians and engineers work tirelessly to ensure that every vessel is repaired efficiently and effectively.

In addition, ADMSI offers a wide range of services beyond just drydocking and repair works. We also provide retrofitting services, allowing Filipino ship owners to upgrade their vessels with the latest technology or comply with new regulations. This comprehensive approach makes us a one-stop solution for all maritime repair needs.

With our state-of-the-art facilities in Tanza, Cavite, experienced Filipino workforce, and commitment to excellence, it’s no wonder that Amaya Dockyard & Marine Services Inc. is considered one of the best drydocking and afloat repair works providers in the Philippines.

Takeaway: Drydocking and Afloat Repair Works in the Philippines Explained

In conclusion, drydocking and afloat repair works in the Philippines offer unique advantages and opportunities for both local and international maritime industries. The country’s strategic location, highly skilled workforce, and competitive prices make it an attractive destination for vessel maintenance and repairs.

One key takeaway is the strong emphasis on quality and efficiency in drydocking facilities in the Philippines. Shipyard operators have invested heavily in state-of-the-art equipment, ensuring that vessels can be serviced promptly without compromising on safety or reliability.

Additionally, the collaboration between shipyards and other related industries, such as steel fabrication, marine engineering, and supply chain management, has contributed to a comprehensive ecosystem that supports efficient repair works. This holistic approach ensures that vessels can be quickly restored to optimal conditions while minimizing downtime and cost.

Overall, drydocking and afloat repair works in the Philippines are integral to maintaining the longevity of vessels operating in Southeast Asian waters. With its world-class facilities, highly skilled workforce, competitive prices, and commitment to quality maintenance services, it is no wonder that more shipowners are choosing this tropical archipelago as their preferred destination for vessel repairs.